Alien Machinary Laser Welding Machine

1. Principles and classification of laser welding machines

A preliminary introduction to laser welding technology is as follows:

A. The principle of laser welding is that the laser beam emitted by the laser is focused on the surface of the welding wire and heated.

B. Let the welding wire heat up and then melt,

C. Wet the gap between welding wires

D. Two metal materials fill the space between the steel plate joints to form a weld,

E. Technology that ultimately achieves a good, solid connection. After laser welding, a strong connection is formed between the metal wire and the metal plate. For example, metal welding wire and metal plate are different materials. The solder layer they form is the fusion of two different materials at high temperatures. Compared with traditional spot welding, this laser welding method has better welding quality. And it is faster, the weldment is stronger and environmentally friendly.

Compared with traditional spot welding, this laser welding method has better welding quality. And it is faster, the weldment is stronger and environmentally friendly.

After understanding the principles of the laser welding machine above. I believe everyone is also interested in the types of laser welding. Generally speaking, laser welding technology is divided into the following types:

Handheld laser welding,

Platform welding,

Galvometer welding,

Mold welding,

Robotic automated welding, etc.

Today I am mainly going to introduce to you our Alien Machinary handheld fiber laser welding machine.

2. Advantages and Disadvantages of Alien Machinay Handheld Laser Welding Machine

The advantages of laser welding machines are as follows:

First of all, the heat affected zone of laser welding is small. Laser welding machines can minimize heat input and have a small heat-affected zone. Therefore, thermal deformation caused by heating of raw materials is also minimal.

Second, laser welding is non-contact. What you can see is that it can be welded, which is a non-contact welding mode. Laser welding is not like traditional welding. Laser welding does not require the use of electrodes. At the same time, there is no concern about electrode contamination or damage. Wear on the laser welding machine and deformation of the welding material are also minimized.

Third, the laser beam is easy to focus by hand. Aligned and guided by optical instruments. It can be placed at an appropriate distance from the workpiece. and guide between machinery or obstacles around the workpiece.

Fourth, the laser beam can be focused on a limited and small area. It automatically welds small, closely spaced metal parts.

Finally, laser welding is easy to use CNC to achieve high-speed automated welding. For example, platform laser welding machine, galvanometer laser welding machine and mold laser welding machine, etc.

There are advantages and disadvantages. The disadvantages of laser welding are as follows:

First, the position of the weldment must be very accurate. During the welding process, the material of the welder must be within the focus range of the laser beam.

Second, the maximum weldable thickness of laser welding is limited by the penetration thickness. Generally speaking, workpieces with a thickness exceeding 19mm are not suitable for laser welding.

Third, laser welding is not recommended for welding highly reflective and thermally conductive materials. Alloys such as aluminum and copper are highly reflective and thermally conductive materials. Therefore, the performance of laser welding will be affected by the laser intensity.

Fourth, the energy conversion efficiency of laser welding is too low, usually less than 10%.

Overall, there are pros and cons to laser welding. But its advantages outweigh its disadvantages. I believe in the near future. Laser welding technology will surely become the most important welding method due to its advantages.

3. Introduction to the application of Alien Machinary laser welding machine

The following laser welding machine is a laser welding machine mainly promoted by Alien Machinary. This is the appearance of a machine we independently developed. We have a professional technical team that can tailor-make machines that meet your requirements according to your needs.

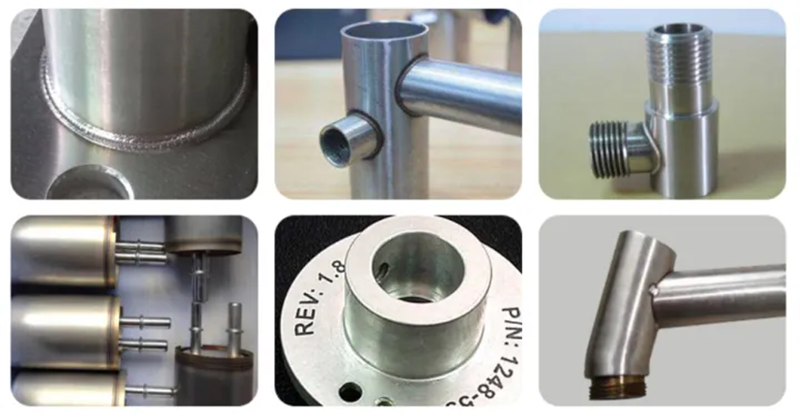

The Alien Machinary laser welding machine can weld a small weld width and a very fast welding speed. The welds are smooth and beautiful, requiring no or simple post-welding treatment. The welds are of high quality and firm, making them very suitable for factory use. We are equipped with this machine with power from 1000 watts to 3000 watts, suitable for welding metal plates from 1mm to 8mm.

At present, laser welding technology has been deeply integrated into our lives. Its application is becoming more and more widespread, gradually replacing traditional welding methods such as gas welding and arc welding. So, in what fields can laser welding machines be used?

Application analysis of special-shaped mechanical laser welding machine:

Broadly speaking, laser welding technology can be applied to

Bathroom industry,

Automotive industry,

Tool manufacturing industry,

Shipbuilding industry,

Precision jewelry industry,

Optical industry,

Hardware industry,

Medical industry, etc.

In addition to the above industrial applications, laser welding technology is also widely used in

Aviation,

Machinery manufacturing,

Hardware,

Building materials and other industries;

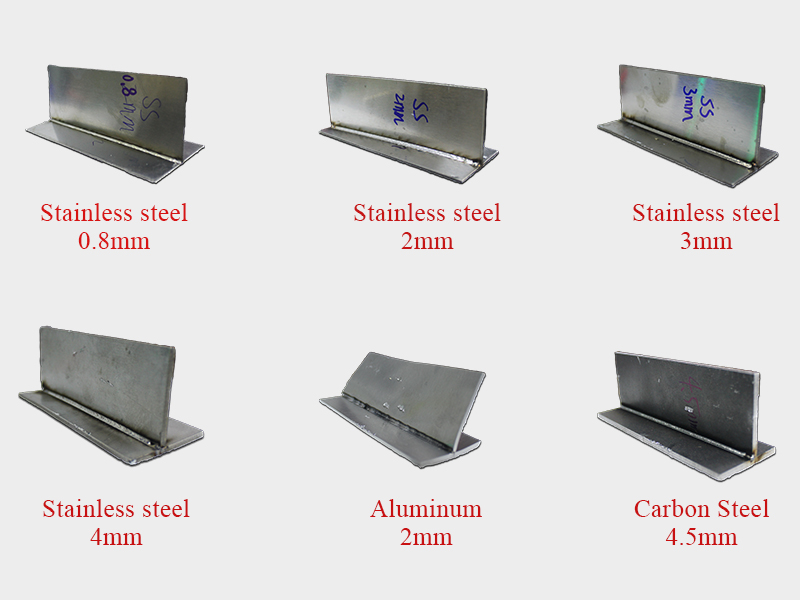

In terms of materials: laser welding machines can weld various metal plates of the same material as well as aluminum and copper. There are also mixed welding of materials such as stainless steel and copper.

It covers areas far beyond traditional welding methods.

4. Introduction to the main accessories of Alien Machinary laser welding machine

The handheld laser welding machine has a simple structure. It mainly consists of the following parts:

laser,

Handheld welding head,

chiller,

Beam transmission and other components.

Not only does the operator not need a workbench when welding. At the same time, operators do not need various complicated fixtures, etc. There are two brands of water coolers commonly used for laser welding: Hanli and Teyu. These two brands of water coolers have been tested by us. Their performance is very stable. It can ensure that the machine can still operate normally in harsh environments.

For handheld swing welding heads, Alien Machinary’s commonly used brands include Relfar and Qilin, as well as RayTools and SUP. Based on pure handheld welding. Alien Machinary also introduced more versatile laser welding equipment.

Three-in-one laser equipment: integrates laser welding, laser cleaning, and laser cutting functions.

Four-in-one laser equipment: It also integrates laser welding and laser cleaning, as well as laser cutting and weld cutting.

5. Sorting out laser welding issues

Many novices have many questions when using or purchasing laser welding machines. Here are some frequently asked questions by customers to share their answers:

1. The difference between laser welding single pendulum and double pendulum. This is a problem that troubles some customers. In fact, as the name suggests, there is only one way to weld the white welded joint. It can only be used for direct welding. The double-swing welding joint has many welding forms: circular and triangular.

2. Wire feeder is standard configuration for our laser welding machine. Some customers will ask, when do we need to use wire feed during the welding process, and why not? When the welding seam between two metal materials requiring a welding machine is large, wire feeding is required. If there is no gap or a small gap between the two materials, wire feeding is not required.

3. Customers often ask, what is the power of the laser welding machine? What is the total consumption? For welding machines with different powers, there is no doubt that their total power consumption is different. For a 1000-watt laser welding machine, the total power consumption is approximately 7.5kw. For a 1.5kw laser welding machine, its total power consumption is about 9kw. For a 2kw laser welding machine, its total power consumption is approximately 11.5kw. For a 3kw laser welding machine, the total power is about 16kw.

4. Is it necessary to use gas during welding? Can an air compressor be used instead? Argon or nitrogen gas is required during the welding process. The argon used here is pure argon, not a mixed gas. Generally, because the cost of argon is low and the cost of nitrogen is high, argon is used more. Laser welding machines can only use gas cylinders and cannot be replaced by air compressors.

5. What is the role of protective gas during the welding process?(1) Protective gas is used to protect the protective mirror. Its function is to prevent slag generated during the welding process from splashing onto the protective mirror.

(2) Block oxygen during welding. A protective air mass then forms. This prevents the metal from oxidizing and turning black after welding. Use argon gas to weld stainless steel, and the weld will be the original color of stainless steel. Use compressed air to weld stainless steel, and the color will be yellow or black after welding. Because there is oxygen in the compressed air, the weld will oxidize quickly. Continuous cleaning machines and pulse cleaning machines use compressed air (nitrogen and argon are also suitable). The function of compressed air is to protect the protective mirror. This is why laser cleaning machines can use air compressors, while laser welding machines must use nitrogen or argon.

Through the above description, I believe that everyone has a deep understanding of laser welding machines. If you have any needs for laser welding machines, please feel free to consult Alien Machinary. We are a company specializing in the production of laser equipment. Our main products are:

Laser welding machine

Laser cleaning machine,

Laser marking machine

Laser engraving machine,

Laser cutting machine, etc.

If you are interested in laser equipment, you are welcome to inquire. Our professional team will provide you with the most professional service and the fastest after-sales service.

EN

EN

AR

AR BG

BG CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LT

LT SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR AF

AF MS

MS BE

BE MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY LB

LB