Classification and Application Case Three of Pulse Laser Cleaning Machine(Ⅲ)

In the last issue, it has been said that the pulse laser cleaning machine can remove rust, paint and rubber. There are also applications such as inks. As long as you use Alien Cleaner 100W and 200W cleaning machines, the effect can reach a very satisfactory level. Interested friends can read the previous content.

What Alien Cleaner recommends to everyone today is the application of high-power pulsed laser cleaning machines. That is our ALCM-500 Pulse Laser Cleaning Machine. Its cleaning effect is better than that of 100 watts and 200 watts. The cleaning efficiency is higher. The relative price is also more expensive. ALCM-500 is widely used in white oil cleaning, black oil cleaning, rust removal, thin rust cleaning and so on.

The book continues from the above, let's take a look at its practical application and cleaning efficiency!

The ALCM-500 produced by Alien Cleaner adopts laser technology. It is able to clean surfaces in a non-contact manner. Compared with traditional cleaning methods: such as mechanical brushing or chemical cleaning. Laser cleaning machines will not cause any damage to the surface. This is very important for some objects with high surface requirements. Such as art and antiques, as well as car parts and so on. In addition, the laser cleaning machine can also clean some hard-to-reach corners and small crevices. It guarantees the integrity of the cleaning effect.

The following is the cleaning case of Alien ALCM-500 pulse laser cleaning machine:

1.laser cleaning paint removal

The laser beam can evaporate paint from the surface in a very short time. Compared with traditional cleaning methods, the ALCM-500 laser cleaning machine can clean faster. It works better. This is very suitable for some occasions that require efficient cleaning. Such as automobile manufacturing and electronics manufacturing.

Compared with traditional cleaning methods, ALCM-500 laser cleaning machine does not need to use any chemical cleaners. It not only reduces the pollution to the environment. At the same time, the cleaning process of the ALCM-500 does not generate any waste. It can avoid the problem of waste disposal. This makes the laser cleaning machine a kind of green cleaning equipment. It fully meets the requirements of modern society for environmental protection.

In addition, pulsed laser cleaning machines also have some other advantages. For example, it can adjust the power and frequency of the laser according to different cleaning needs. Thus adapting to different surface materials and paint types. At the same time, the laser cleaning machine can also be operated automatically. It greatly reduces the need for manual operations and improves cleaning efficiency and quality.

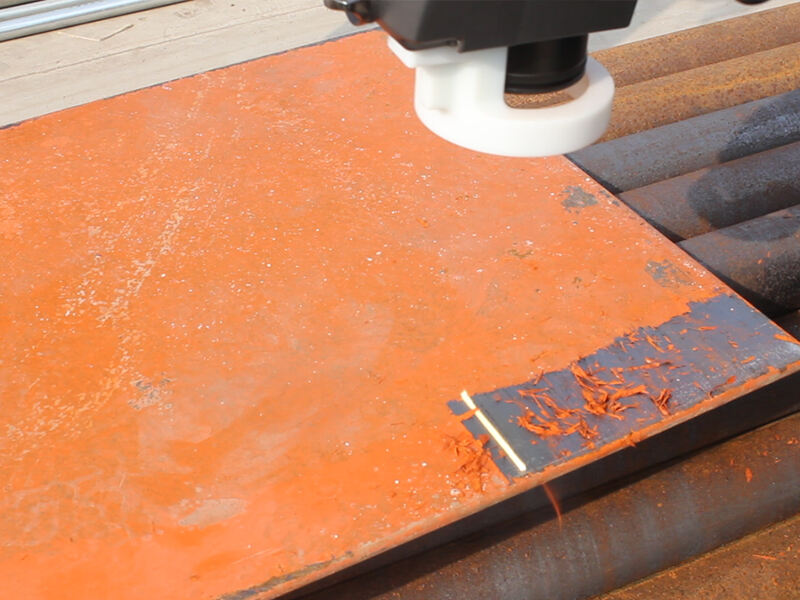

2. Thick rust layer cleaning (>50um)

Thick rust layer (>50um) cleaning, the cleaning efficiency is about 4m²/h, the picture shows the real shot of aluminum oxide cleaning by Alien Cleaner.

The picture above shows the cleaning of thick rust layer (>50um), and the cleaning efficiency is about 4m²/h

3.Epoxy paint laser cleaning

In particular, explain the application of ALCM-500 laser cleaning machine in epoxy paint. This material is composed of epoxy resin, extender pigment and curing agent. Epoxy paint is a common paint. Its wear resistance, acid and alkali resistance and heat resistance are better than ordinary paints. It is mainly used in metal anti-corrosion and chemical anti-corrosion of automobile primers. However, epoxy paint will cause dirt and aging during use, as well as problems such as peeling. It affects appearance and performance. Traditional cleaning methods may result in surface damage or incomplete removal of epoxy paint. But the pulsed laser cleaning machine can act instantly through the high-energy laser beam. It evaporates or strips epoxy paint quickly. Not only effectively remove epoxy paint, but also avoid surface damage.

Secondly, ALCM-500 can be used for the purification of epoxy paint. In some special application areas: such as food processing and medical equipment. The industry has high requirements on the purity of epoxy paint. Traditional cleaning methods may not be able to completely remove dirt and impurities on the surface of epoxy paint. The ALCM-500 pulse laser cleaning machine can act instantly through the high-energy laser beam. It can quickly evaporate or strip dirt and impurities. Make the surface of epoxy paint meet higher purity requirements.

ALCM-500 can also be used for fine processing of epoxy paint. On some small and complex parts. Epoxy paint coatings can have problems such as unevenness and varying thicknesses. Greatly affected the quality and performance of the product. Traditional cleaning methods may not be able to fine-tune these small and complex parts. The pulse laser cleaning machine can adjust the parameters of the laser beam. It can precisely control the position and depth of cleaning, as well as the intensity. It can finely process the epoxy paint and improve the quality and performance of the product.

The ALCM-500 removes epoxy paint efficiently and precisely. Also decontaminates epoxy painted surfaces. It can realize the fine processing of epoxy paint. With the continuous progress of science and technology. It is believed that the application of pulse laser cleaning machines in epoxy coatings will become more and more extensive. It will definitely bring better epoxy paint cleaning solutions to various fields.

4.The difference between high power pulse laser cleaning machine and low power pulse laser cleaning machine

The power of high-power pulse laser cleaning machine and low-power pulse laser cleaning machine is different. There are the following differences between the two, please follow me.

1.High-power pulse laser cleaning machine has stronger cleaning ability.

High-power pulsed laser cleaners typically run between 500 watts and above. It is capable of producing higher energy laser beams. Contaminants on the target surface can thus be removed more effectively. The power of low-power pulsed laser cleaners is usually between 100 watts and 300 watts. Its cleaning ability is relatively weak. But customers can choose the pulse laser cleaning machine equipment that suits them according to their own choices.

2. The high-power pulse laser cleaning machine is suitable for a wider range of applications.

Due to its higher power, high-power pulsed laser cleaners can be used to clean larger areas and more difficult targets. For example, oil stains and coatings on metal surfaces, as well as oxides. The low-power pulse laser cleaning machine is mainly suitable for cleaning small-sized objects. Such as electronic devices and precision instruments, etc. See the previous article for details.

3. The working principle is slightly different.

High-power pulsed laser cleaners generate high-energy pulses by focusing a laser beam. It subjects pollutants to high temperature and high pressure in a very short period of time. Thereby vaporizing and melting or peeling off instantly. The low-power pulse laser cleaning machine directly ablates or strips the surface pollutants of the target object through a lower-energy laser beam.

4. Security risks.

Due to the high energy density of the high power laser beam. It requires stricter safety measures when using high-power pulsed laser cleaners. Avoid direct exposure of the laser beam to human eyes and skin. so as not to cause damage. The low-power pulse laser cleaning machine has relatively high safety due to its low power. Of course, if you choose high-power cleaning equipment. We will provide you with high-quality protective glasses and other supplies for free.

To sum up, there are some differences between the two in terms of cleaning ability, application range, working principle and safety. Choosing the right cleaning model needs to be determined according to the specific cleaning needs.

In conclusion, the pulsed laser cleaning machine relies on professional style and efficient cleaning ability. It is gradually becoming an important equipment in the cleaning industry. It has the advantages of non-contact and high efficiency, as well as environmental protection and energy saving. Believe that with the continuous advancement of technology. Pulse laser cleaning machines will be applied to more fields. And bring people a more convenient and efficient cleaning experience. In the future, we will continue to update the relevant applications and cleaning efficiency of pulse laser cleaning machines. If you are interested, you can follow us. For more videos follow our YouTube account:

https://www.youtube.com/channel/UCD2m8XAbHpKQGp383JsAuAg

EN

EN

AR

AR BG

BG CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LT

LT SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR AF

AF MS

MS BE

BE MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY LB

LB